Split type internal mixer CF-2

Split type internal mixer CF-21、 The working principle of the mixing (internal mixing) granulation integrated machine:The most obvious feature of a continuous mixer is continuous feeding, which provid

Service:

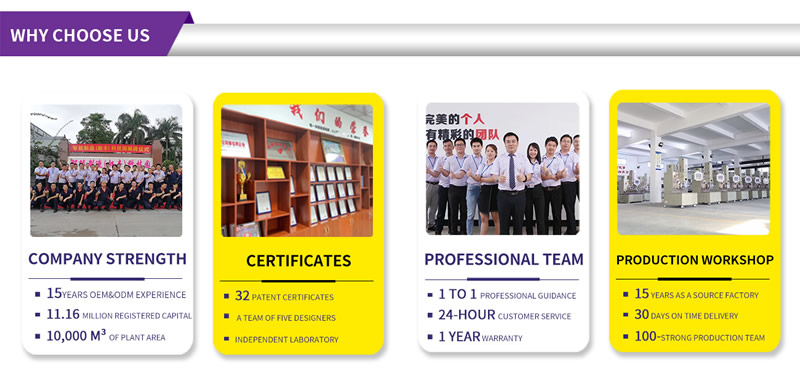

1). Any inquires will be replied within 24 hours

2). Before-sale and after-sale service, overseas engineer service is available, All products have been strictly quality test in our factory before packing

3). Free technical training until customers can operate independently

4). 12 months warranty

5). long-term providing quick-wear parts

6). life time technical support service

Split type internal mixer CF-2

1、 The working principle of the mixing (internal mixing) granulation integrated machine:

The most obvious feature of a continuous mixer is continuous feeding, which provides a constant feeding speed and ensures a constant feeding rate. It can increase the rotor speed and obtain greater shear force. The structure of the continuous mixer, or slightly close the discharge door, increases the discharge angle temperature, and the mixer operates under normal pressure to form an independent mixing environment, completely unaffected by molding requirements.

2、 Equipment advantages of the mixing and granulation integrated machine:

1. The integrated mixing (internal mixing) machine has no dust flying, and the pressurized chamber internal mixing machine has dust flying, eliminating the problem of formula pollution. The storage, measurement, and quantitative feeding function effectively avoids pollution caused by the dust generated by workers pouring materials.

2. The mixing (internal mixing) granulation unit has a small footprint and low floor requirements. The mixing screw can be disassembled and cleaned at will, eliminating the problem of formula pollution.

3. Automation: Machine automation combination, continuous internal mixer application, reducing manual operations and improving production efficiency.

4. Quality: The mixer (internal mixing) is an integrated machine that operates continuously and has good stability in discharge quality, greatly improving efficiency, which is 1-2 times that of traditional machines. Mixing and granulation can be carried out simultaneously, effectively saving the traditional time of granulation after mixing is completed, achieving the goal of energy conservation and efficiency, and significantly reducing the production costs of manufacturers.

5. High degree of automation and production efficiency;

6. Continuous production, stable formula, and excellent product quality

7. Excellent mixing effect and better dispersion effect.

8. To achieve automatic control and generation, it is necessary to cooperate with a mixer, weight loss weighing and measuring equipment.

9. Continuous internal mixing unit, there is no obvious high peak current during the mixing process, the current is stable and stable, and the motor saves energy significantly.

Previous:Continuous mixer