75L dual hydraulic mixer

75L dual hydraulic mixerThe production type internal mixer has the advantages of small size, simple structure, easy operation, low energy consumption, and convenient use and maintenance. It adopts Tai

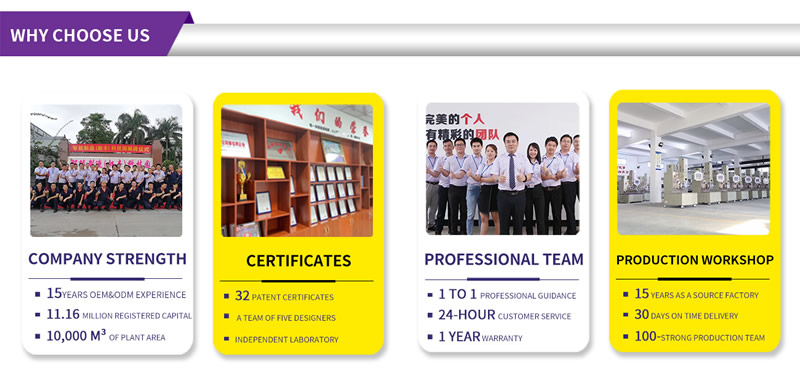

Service:

1). Any inquires will be replied within 24 hours

2). Before-sale and after-sale service, overseas engineer service is available, All products have been strictly quality test in our factory before packing

3). Free technical training until customers can operate independently

4). 12 months warranty

5). long-term providing quick-wear parts

6). life time technical support service

75L dual hydraulic mixer

The production type internal mixer has the advantages of small size, simple structure, easy operation, low energy consumption, and convenient use and maintenance. It adopts Taiwanese drawing technology and is produced in mainland China, with the quality of imported machines and the price of domestic machines. The internal mixer produced by our company has achieved industry standards in terms of powder leakage sealing effect, temperature control, and machine rotor wear resistance.

The price and mechanical principles of the production 75L dual hydraulic mixer are as follows:

1. The core technology and main components come from Taiwan

2. Adopting the "M-W" pressurized and cast mixing tank, it is not only sturdy and wear-resistant, but also ensures uniform material mixing.

3. The combination of automatic temperature control system and time control system makes its operation precise and easy to understand

4. According to the needs of the mixture, it can be divided into manual and automatic control, which is easy to operate.

According to the design characteristics of the rotor blades of this machine, the mixing speed is about one-third faster than the previous year (about 5-7 minutes), which is about three times faster than traditional roller machines.

6. Adopting high-efficiency motors, with good power transmission, power saving, and long service life.

7. The mixing tank of this machine is made of advanced special steel, and the surface is treated with wear-resistant steel. The surface is electroplated with hard chromium, which has excellent wear resistance and a lifespan of 1-2 times longer than traditional ones.

8. The mixing blades are also treated with wear-resistant steel and plated with hard chromium, providing excellent wear resistance.

9. The mixing shaft is made of high-grade special steel, processed several times, and finally normalized, with the longest service life and less prone to fracture.

10. The electrical components are imported brand products, ensuring stable operation.

Previous:10000 horsepower drop type int