Experimental mixer

It is suitable for mixing and kneading various chemical materials such as various rubber products, EVA, rubber, synthetic rubber, Hot-melt adhesive, etc. Under the stirring of the stirring blades, the

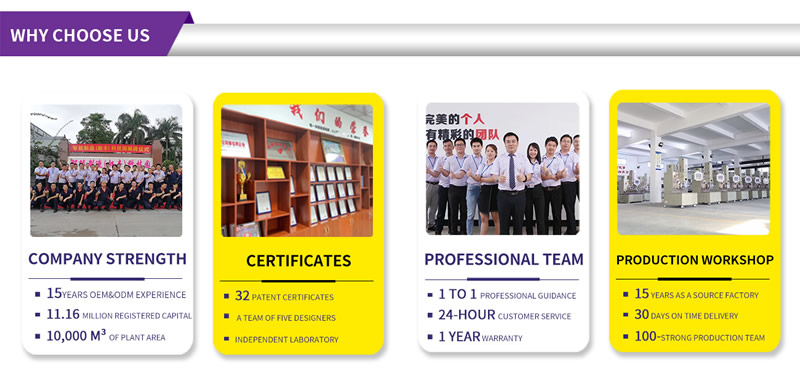

Service:

1). Any inquires will be replied within 24 hours

2). Before-sale and after-sale service, overseas engineer service is available, All products have been strictly quality test in our factory before packing

3). Free technical training until customers can operate independently

4). 12 months warranty

5). long-term providing quick-wear parts

6). life time technical support service

It is suitable for mixing and kneading various chemical materials such as various rubber products, EVA, rubber, synthetic rubber, Hot-melt adhesive, etc. Under the stirring of the stirring blades, the materials quickly melt and pinch together. By controlling the appropriate temperature (with cooling or heating methods), the raw materials are mixed evenly to achieve the best effect of year-on-year mixing.

Main functions:

By rotating the rotor, a strong shear force is applied to the material and it is stirred in all directions to achieve uniform mixing of the material. Utilizing the stirring and mixing effect of the rotor to trigger strong reactions between different components in the material, ensuring sufficient reaction.

The 2L internal mixer is the first choice for mixing and semi forming experiments of rubber and other plastic product raw materials.

Technical parameters of small internal mixer:

1. Automatic temperature control to ensure uniform material distribution.

2. It can be divided into manual and automatic control according to the needs of the mixture, and the operation is simple and easy to understand.

Mixing capacity: 2L

Drive motor: 5.5KW

Flipping motor: 0.75KW

Turning angle: 110 °

Production: 1.5-2.8KG/time

Electric heating: 800W

Appearance: approximately 1460 * 880 * 2100mm

Machine weight: approximately 1000KG

Advantages of Changfeng Small Internal Mixer:

1. Adopting Taiwanese technology and professional designers to improve the drawings.

2. The entire series is equipped with Dongyuan frequency converters as standard, with adjustable speed.

3. The flipping motor is equipped with a brake motor, ensuring stable flipping and material pouring.

4. All low-voltage appliances adopt international well-known brands to ensure efficient operation of the machine.

5. Special design is adopted to prevent powder leakage.

6. Equipped with temperature control components imported from Taiwan as standard, it has a sensitive response and fast automatic temperature control.

Previous:Wire and cable mixer

Next:Open close mixer