Split type internal mixer

Split type internal mixerStainless steel powder metallurgy granulator, MIM specialized granulator features:1. Control functions such as sound and light fault alarm and quick locking of fault points. A

Service:

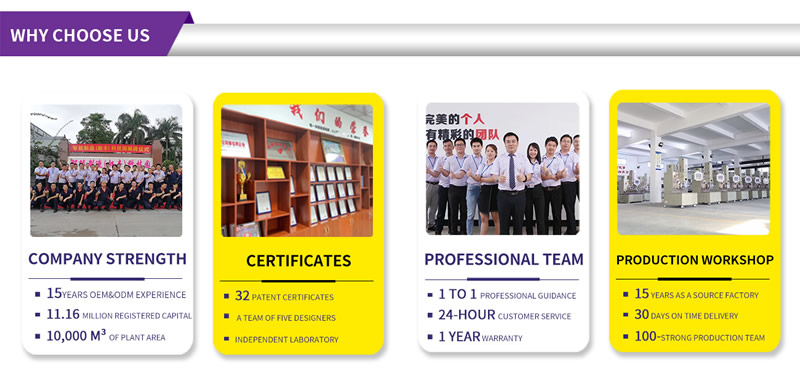

1). Any inquires will be replied within 24 hours

2). Before-sale and after-sale service, overseas engineer service is available, All products have been strictly quality test in our factory before packing

3). Free technical training until customers can operate independently

4). 12 months warranty

5). long-term providing quick-wear parts

6). life time technical support service

Split type internal mixer

Stainless steel powder metallurgy granulator, MIM specialized granulator features:

1. Control functions such as sound and light fault alarm and quick locking of fault points. All units in contact with materials are made of stainless steel, with exquisite details, complete and reliable, energy-saving and durable

2. The accuracy of the temperature control system ensures the sensitivity of materials to temperature. Equipped with a cooling water system circulation device

3. The components imported from Taiwan (Shilin, Tiande, Yangming) used in low-voltage electrical appliances have low failure rate, energy saving and stable operation.

4. Especially, foreign technology is used to ensure and control the risk of mold bursting due to uncontrollable pressure in the material barrel and mold head

The combination of dual pull forced feeding system and single screw technology not only meets the high requirements of secondary continuous high mixing of materials, but also solves the labor and time consumption of traditional block crushing. It also enhances the production capacity, environmental protection, and automated continuous operation of the enterprise image

6. The clamping design of the mold head adopts a C-type clamping design, which is easy to operate, has good clamping stability, high anti burst coefficient, and has been highly praised by both new and old customers for its safety performance.

7. Our company adopts imported speed control components from abroad, with digital display and clear speed display.

8. The cutting system adopts a guide rail type sliding, with accurate reciprocating center positioning, convenient and fast disassembly of screws, which greatly improves your production efficiency. It can achieve no residue in material cleaning, and has high requirements for pollution prevention of precious materials. It is customized.

Stainless steel powder metallurgy granulator, advantages of Nin specialized granulator:

1. Screw and barrel: The material is 38CrMoALA nitrided, HV950-1050 nitrided, depth 0.6-0.75mm, brittleness not greater than Grade II, and the surface of the screw is wear-resistant;

2. Heating section: Adopting high-quality cast aluminum heater

3. Reduction gearbox: A high-precision hard tooth surface gear transmission device with thrust seat designed by the ZLYJ series professional for single screw rubber and plastic extruders is adopted. The design adopts various technical specifications specified in JB/T8853-2001 "Cylindrical Gear Reducers", and the output shaft is made of high-strength 42CrMo, while other gears and shaft parts are made of high-strength 20CrMnTi material; The gears are processed through carburization, quenching, and grinding processes, resulting in high precision and hardness;

4. According to the different states of the materials, the feeding system adopts various structural forms, including single screw, double screw, double screw non meshing type, hollow spring type, double step type, and metering pump for volumetric feeding? Material. It can also be equipped with weightless metering feeding to meet higher metering requirements.

5. Control functions such as machine interlocking, sound and light fault alarm, and quick locking of fault points. All units in contact with materials are made of stainless steel, with exquisite details, complete and reliable, energy-saving and durable

Previous:Production type double rotor c

Next:Continuous mixer